Plastic essentials have blended into our lives making our lives much easier with longer lasting and low maintenance products. With years passing by the ancient plastic manufacturing processes evolved within.

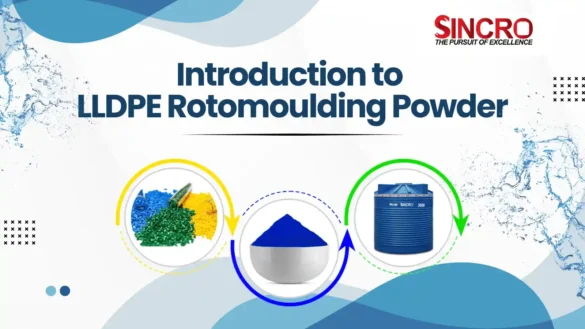

In this plastic manufacturing market, rotational moulding is a prominent process for creating hollow, seamless, and durable products. At the heart of this process is LLDPE rotomoulding powder, a material that brings exceptional qualities to the table.

This informative blog delves into the intricacies of LLDPE rotomoulding powder, exploring its composition, benefits, and broad range of applications.

What is LLDPE Rotomoulding Powder?

LLDPE stands for Linear Low Density Polyethylene rotomoulding powder. It is a type of polyethylene specifically engineered for rotational moulding applications. It is produced as a copolymer of ethylene and one or more alpha-olefins, like butene, hexene, or octene.

This unique molecular structure gives LLDPE its exceptional properties, including higher tensile strength, impact resistance, and puncture resistance compared to other polyethylene variants like HDPE (High-Density Polyethylene) and LDPE (Low-Density Polyethylene).

These properties make LLDPE particularly suitable for applications requiring durability and flexibility, such as in the production of tanks, containers, and outdoor furniture.

What are the Characteristics of LLDPE Rotomoulding Powder?

1. Molecular Structure

The molecular structure of LLDPE features short branches along the polymer chain. These branches contribute to its flexibility and impact resistance, as well as its ability to maintain strength and integrity under stress.

2. Impact Resistance

One of the standout features of LLDPE is its excellent impact resistance. This makes it ideal for applications where the product is subjected to physical stress or rough handling. The material can absorb energy from impacts without cracking or breaking.

3. Flexibility and Elongation

LLDPE exhibits significant flexibility and elongation at break, which means it can stretch and deform without breaking. This property is particularly valuable for products that need to accommodate movement or expansion.

4. Uniform Wall Thickness

During the rotomoulding process, LLDPE ensures a consistent wall thickness throughout the product. This uniformity is crucial for maintaining structural integrity and performance across the entire surface of the product.

5. Chemical and UV Resistance

LLDPE has inherent resistance to many chemicals, including acids, bases, and solvents. It can also be treated with UV stabilizers to enhance its resistance to ultraviolet radiation, making it suitable for outdoor use where it will be exposed to sunlight.

6. Low Density and Lightweight

Despite its strength and durability, LLDPE is a low-density material, which makes it lightweight. This characteristic reduces shipping costs and makes it easier to handle.

Benefits of LLDPE Rotomoulding Powder

-

- Durability and Longevity – LLDPE products are known for their longevity. The material’s resistance to impact, chemicals, and environmental factors ensures that products retain their functionality and appearance over time.

-

- Design Flexibility – The rotomoulding process allows for complex and intricate designs. LLDPE’s properties facilitate the creation of products with complex shapes, internal structures, and features that are difficult to achieve with other moulding techniques.

-

- Ease of Processing – LLDPE is well-suited for the rotomoulding process, which involves heating the powder in a mould and rotating it to ensure even coating. The material’s thermal properties allow for smooth processing and high-quality finishes.

-

- Cost Efficiency – LLDPE is a cost-effective material. Its relatively low price and the efficiency of the rotomoulding process make it an economical choice for producing a wide range of products.

-

- Recyclability – As a thermoplastic, LLDPE can be recycled. This contributes to environmental sustainability by reducing waste and promoting the reuse of materials.

Bottom Line

LLDPE rotomoulding powder is a versatile material known for its excellent combination of flexibility, durability, and cost-effectiveness, which makes it an invaluable asset in the rotational moulding process.

With its unique properties, LLDPE enables the production of a diverse range of high-quality and functional products across a wide spectrum of industries. As the demand for adaptable and strong plastic materials continues to rise, LLDPE stands out as the top choice for manufacturers seeking to deliver innovative and dependable solutions.

To shop the best LLDPE rotomoulding powder manufacturer with affordable rates, visit Sincro and find your desired requirements.

Frequently Asked Questions

1. What is LLDPE used for?

LLDPE has penetrated almost all traditional markets for polyethylene; it is used for plastic bags and sheets (where it allows using lower thickness than comparable LDPE), plastic wrap, stretch wrap, pouches, toys, covers, lids, pipes, buckets and containers, covering of cables, geomembranes, and mainly flexible tubing.

2. What is the difference between LDPE and LLDPE?

LLDPE is used in coating applications to protect liquid containers content. LDPE is used in light packaging materials like plastic wraps. LLDPE is better than LDPE and HDPE, as its short branches can slide against each other, and it has more flexibility.

3. Is LLDPE plastic safe?

LLDPE food safe resin is a high-performance, FDA-compliant plastic specifically designed for food grade packaging applications. Made from post-commercial shrink wrap and film collected only from vetted food packaging suppliers, this lldpe plastic aligns with strict food packaging materials standards.

4. Which is stronger HDPE or LLDPE?

LLDPE: While LLDPE also offers good chemical resistance, it may not be as suitable for storing highly aggressive chemicals or at elevated temperatures as HDPE. Therefore, HDPE is typically chosen for applications where superior chemical resistance and strength are critical

5. What is the major use of LLDPE?

LLDPE is commonly used in applications where these properties are important, such as in packaging, films, and blown or injection-moded parts. It is also recyclable, which makes it an environmentally-friendly choice.