Rotational moulding, often known as rotomoulding, has become one of the most versatile manufacturing processes for producing durable and lightweight plastic products. The LLDPE Rotomoulding Powder is the most commonly used material in this manufacturing process because of its excellent properties, affordability and flexibility among other materials.

In this guide, we will look at LLDPE Rotomoulding Powder in detail including the properties, applications, advantages and how to evaluate a LLDPE rotomoulding powder manufacturer for your specific needs.

What is LLDPE Rotomoulding Powder?

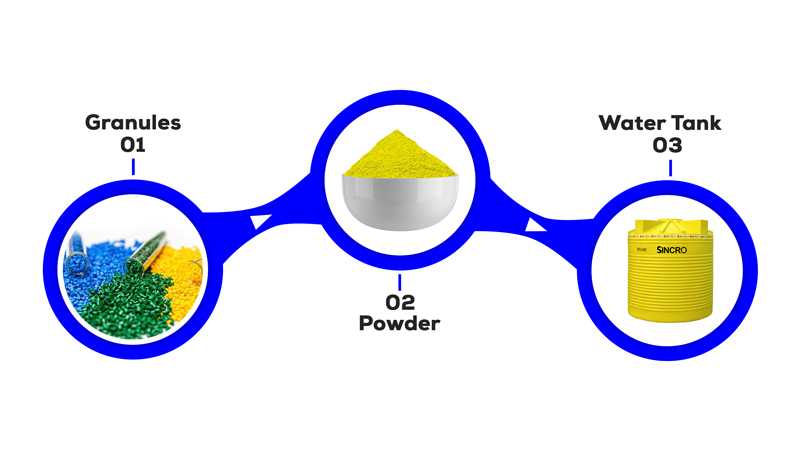

LLDPE (Linear Low-Density Polyethylene) rotomoulding powder is an advanced plastic specifically engineered and aimed to have unique attributes and performance for rotational moulding. It is made by grinding polyethylene resins into fine powder particles that can easily melt, flow, and uniformly coat the inside of moulds during the rotomoulding process.

When compared to other plastics, LLDPE powder for rotomoulding offers greater impact resistance, better crack resistance and greater flexibility. This is the reason it is widely used for producing a variety of products such as storage tanks and children’s toys.

Learn more about LLDPE Rotomoulding Powder

Properties of LLDPE Rotomoulding Powder

Some key properties that make LLDPE powder the preferred choice for rotomoulding include:

- High Impact Strength – Parts produced with LLDPE rotomoulding powder will last longer when received with accidental impact, drops, and rough handling. All is necessary for industrial or consumer-based confidence.

- Excellent Weather Resistance – For outdoor products, LLDPE powder comes in UV-stabilized grades to facilitate essential resistance to rain, sunlight and temperature change over time. This is important for durability, for example, with storage tanks, playground equipment, and road barriers.

- Chemical Resistance – LLDPE rotomoulding powder has good levels of resistance to many acids, bases and organic solvents. Resistant chemical aplications make this material a preferred option for containers for agriculture, chemical and food storage.

- Flexibility & Toughness – In comparison to brittle plastic types, LLDPE rotomoulding powder has a more inherent flexibility factor preventing stress cracks thus extending product lifespan.

- Good Flow & Processing Characteristics – The LLDPE powder melts uniformly, has good flow and coats mould surfaces uniformly while the parts are being fabricated using rotational induction moulding.

- Low Density & Lightweight – While being very durable the LLDPE powder remains relatively lightweight which is advantageous for products that are intended to be portable and handy.

Benefits of Using LLDPE Rotomoulding Powder

When choosing LLDPE powder for rotational moulding there are multiple benefits over other materials:

- Cost-Effective Manufacturing – Compared to materials such as HDPE or PVC, LLDPE offers the best performance-to-price ratio; it is compatible with both small and large-scale production.

- Versatile – It is produced in multiple grades and colors, and can be customized specifically for various uses (household, industrial, and automotive, etc.).

- Durable & Long Lasting – Products will maintain their strength and integrity when used outside, holding large amounts of material, or exposed to chemicals.

- Hygienic & Safe – LLDPE rotomoulding powder is safe for use for applications such as water tanks or food storage bins, as well as children’s toys.

- Design Flexibility – Due to its flow properties, manufacturers can build hollow shapes or complicated designs ensuring material integrity and strength.

- Low Maintenance – LLDPE products have low maintenance because they are resistant to rust, corrosion and weathering.

- Eco-Friendly – Many LLDPE powders can be recycled which allows companies to take a more sustainable approach to minimizing their environmental impact.

Applications of LLDPE Rotomoulding Powder

LLDPE Rotomoulding powder is a common product used across all industries where practicality and functionality is needed. Examples of products made using LLDPE Rotomoulding powder include:

- Water & Chemical Storage Tanks – Strong, robust, hygienic, and weather resistant tanks for domestic and household, agricultural and industrial purposes.

- Automotive Industry – A range of products, some of which require impact resistant properties; such as fuel tanks, dashboards, fenders, ducts and protective covers.

- Agricultural Supplies – Seed boxes, fertilizer bins, pesticide storage drums, and irrigation parts.

- Household & Lifestyle Products – Dust bins, garden furniture, planters, laundry baskets and decorative items.

- Children’s Products & Toys – Playground slides, outdoor toys and play equipment as LLDPE is durable and has a non-toxic nature.

- Industrial Applications – For determining products such as pallets, crates, road barriers, traffic cones, and boxes used for heavy duty applications.

- Marine & Outdoor Equipment – LLDPE can be installed for constructing high strength and water resistant items including floating devices, boats and kayaks, and other water sport equipment.

- Medical & Healthcare Products – You can use specific grades of LLDPE powder to manufacture safe and hygienic medical storage containers.

Choosing the Right LLDPE Powder Manufacturer

It is necessary to select the right supplier of LLDPE rotomoulding powder for durability/quality; the following are details to consider for suppliers:

- Experience & Reputation – Typically, the best suppliers are manufacturers that have experience.

- Product Range – Confirm the supplier carries a range of grades and colors.

- Quality Standards – Confirm the material meets international quality standards.

- Customer Service – Look for prompt responses from suppliers, whether you ask a question or place a bulk order.

- Competitive Pricing – Pricing should be clear and remain consistent with product choices.

Sincro provides LLDPE rotomoulding powder suitable for a wide range of industries with enhanced quality levels.

Final Thoughts

LLDPE rotomoulding powder is the composition of the rotational moulding industry due to it being versatile, durable, and advantageous. Whatever you are manufacturing from water tanks to automotive to industrial parts, this material can be your path to success.

When you work directly with a credible LLDPE powder supplier, you will have better material quality, better pricing and shorter lead times. Sincro is a reputable name in the industry where you can find reliable solutions.

FAQ

1. What is LLDPE rotomoulding powder?

LLDPE rotomolding powder is a type of polyethylene resin that has been ground down to a powder, designed for long-lasting use in the creation of plastic items by means of rotational molding.

2. What kinds of products can be made with LLDPE rotomolding powder?

LLDPE is utilized in the production of water tanks, industrial containers, toys, outdoor furniture, as well as interior automotive parts.

3. What is the LLDPE rotomoulding powder price?

LLDPEpowder price will vary according to grade, fillers, and quantity purchased. It is recommended to reach out directly to a reputable LLDPE powder producer for a quote.

4. Where can I buy high-quality LLDPE powder?

You really should reach out to a retailer, like Sincro, who has an established reputation in the sale of high-grade rotomolding powder.